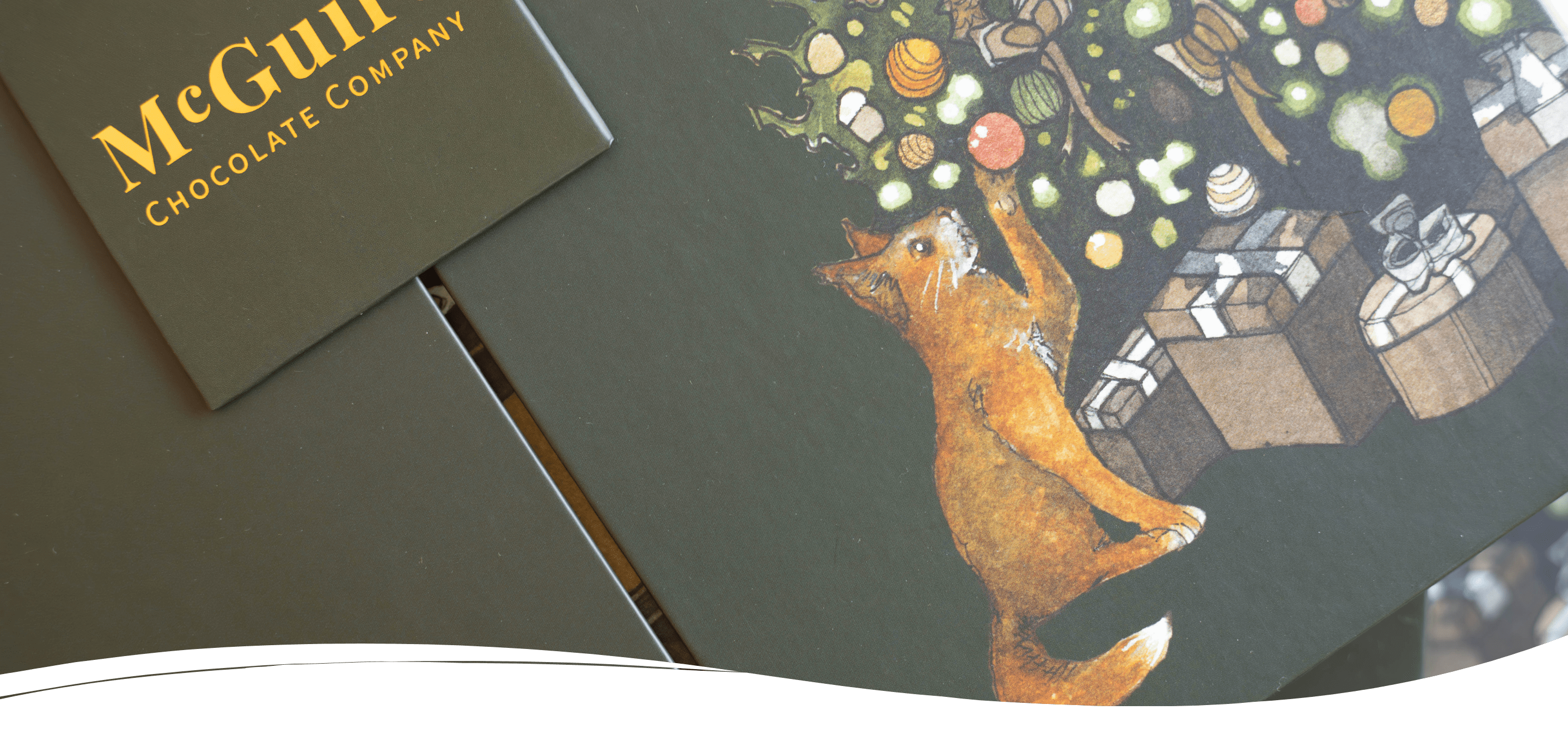

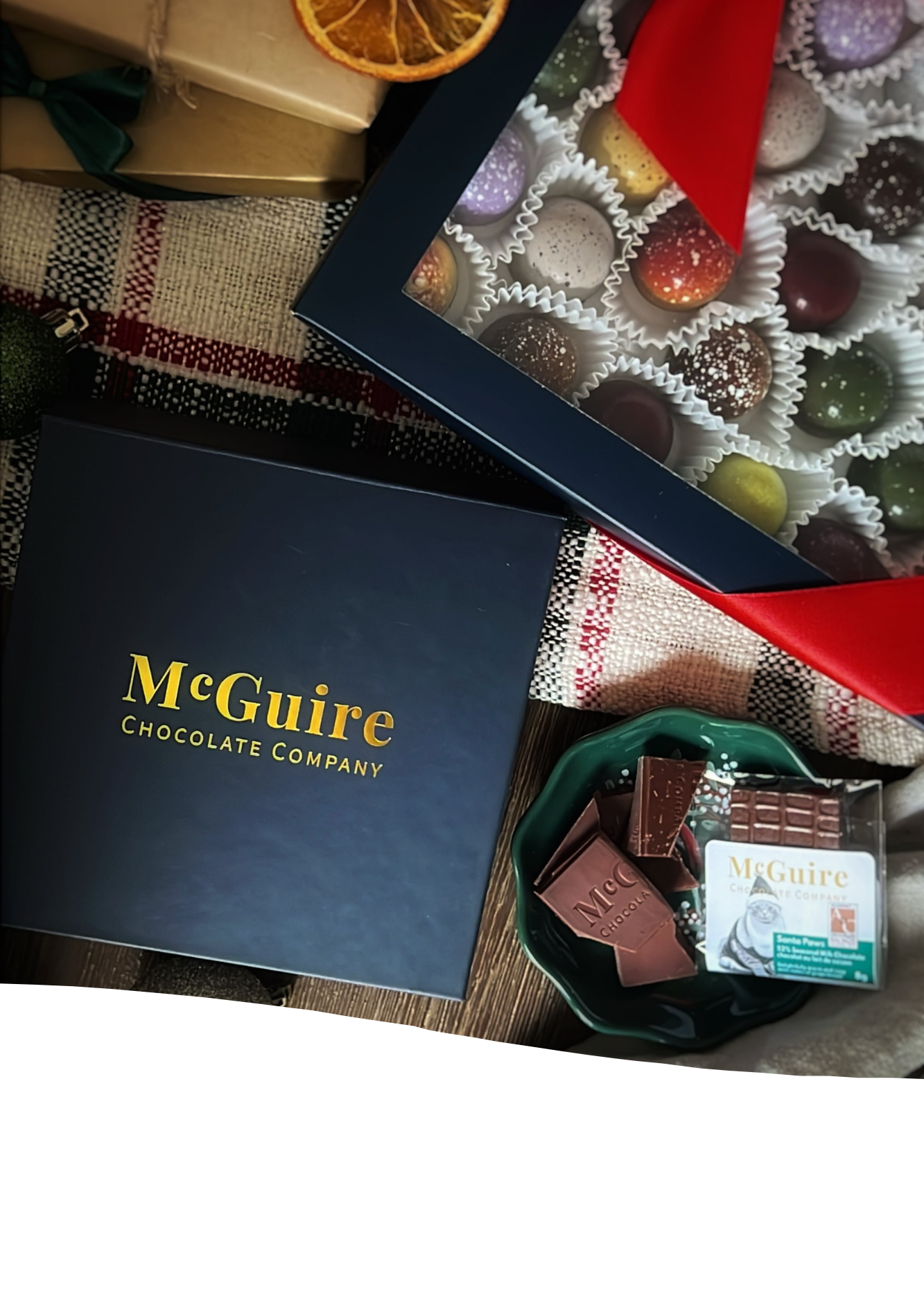

Luxurious

Sweeten your Countdown

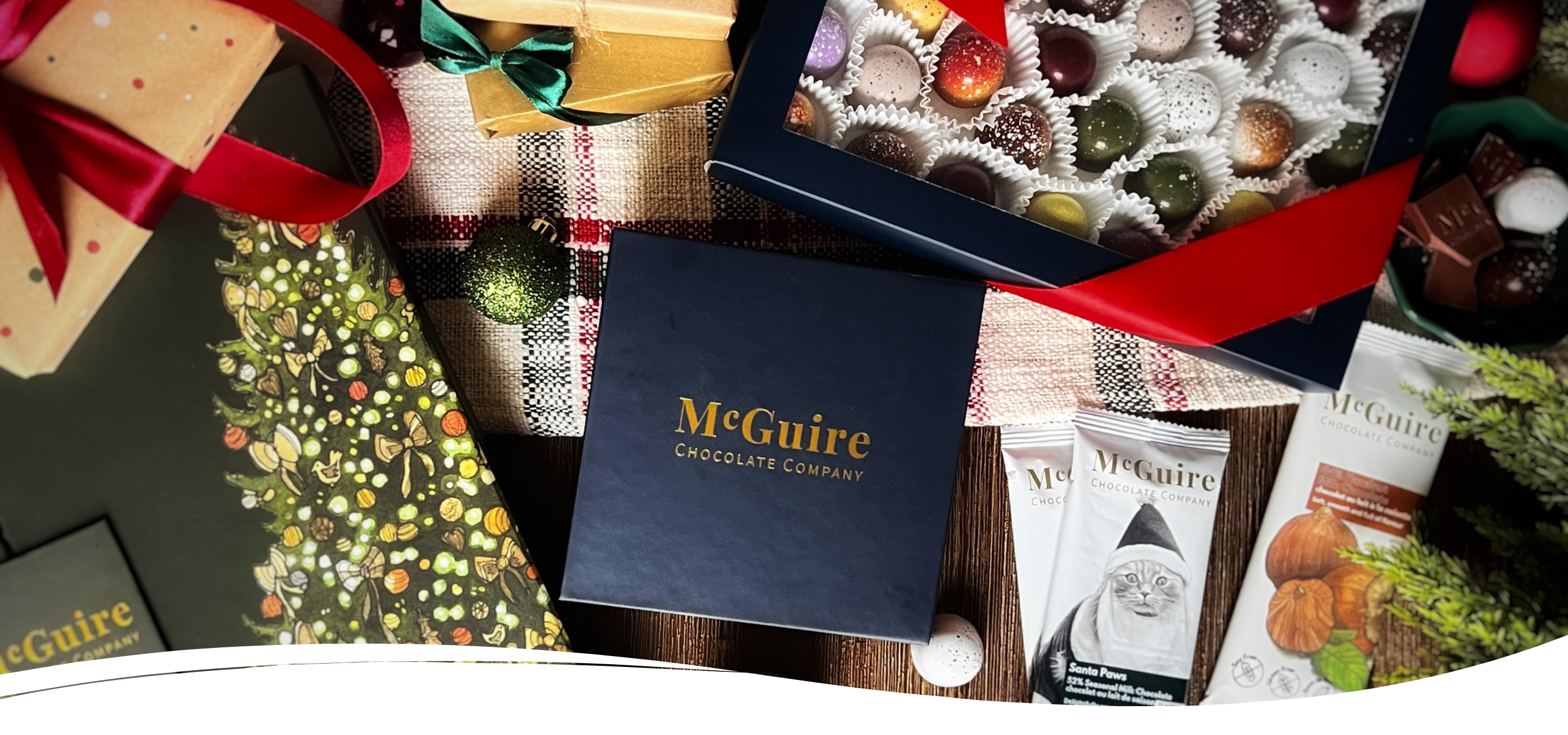

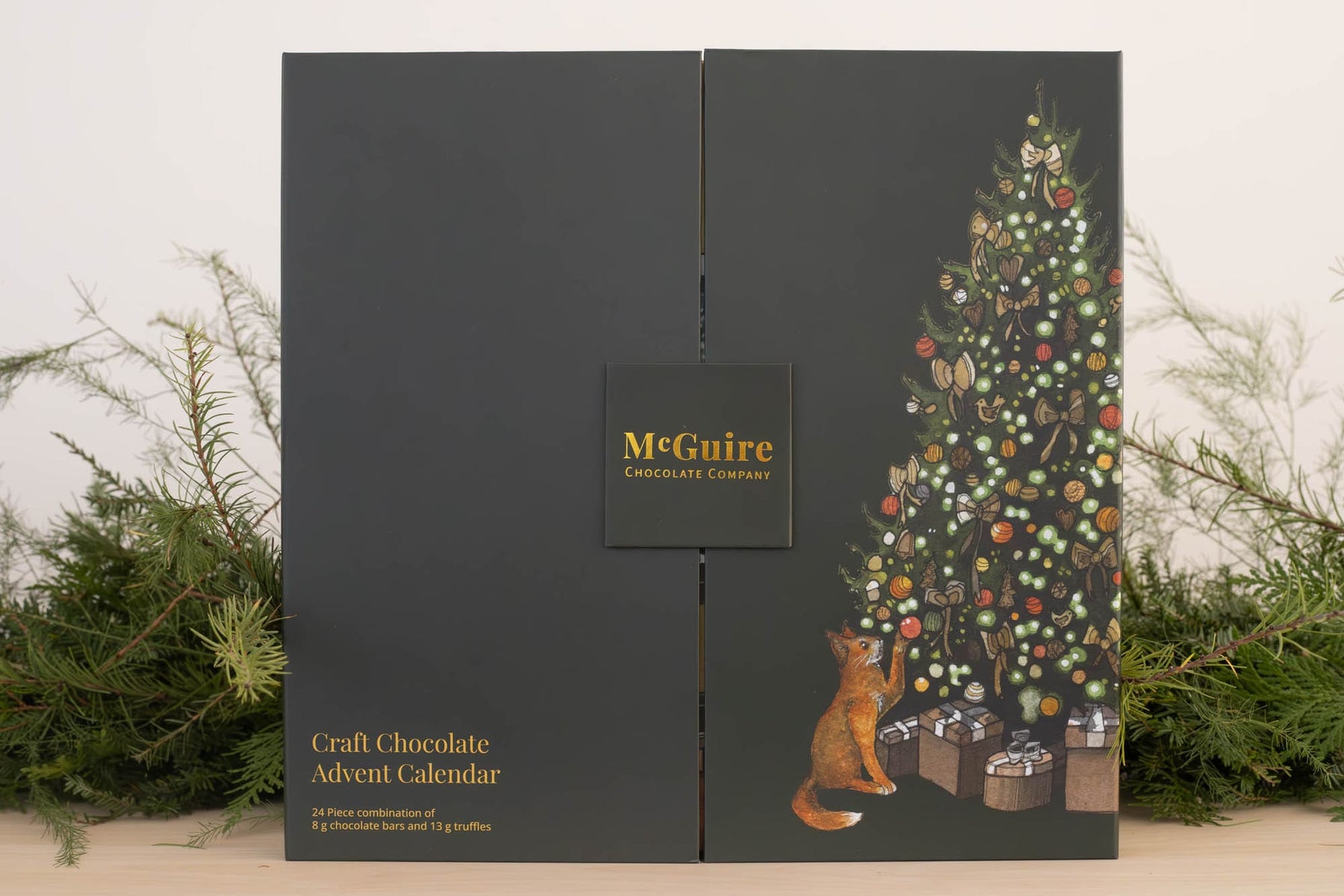

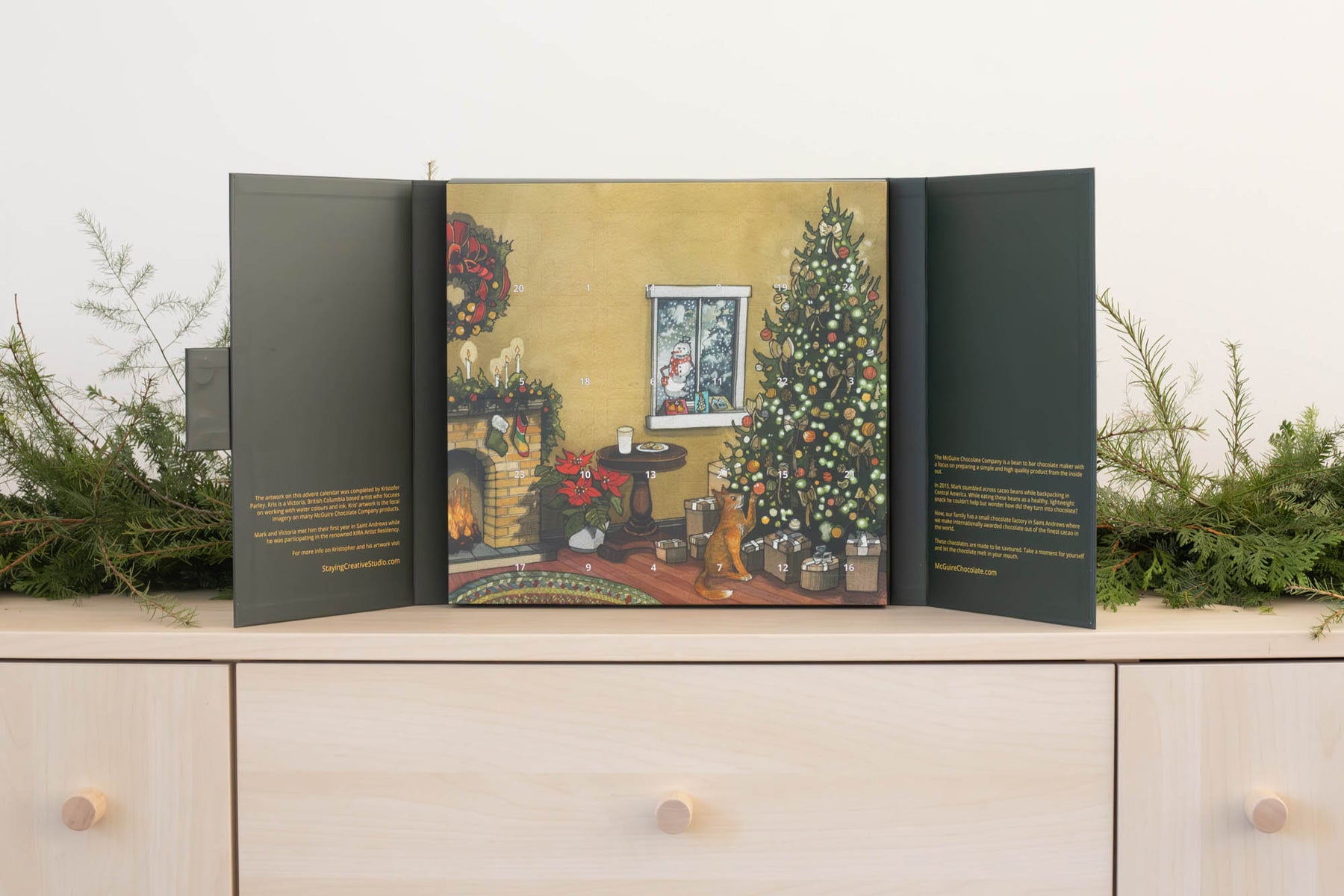

Chocolate Advent Calendar

Chocolate Advent Calendar

Classic

McGuire Chocolate

174 Water Street

St. Andrews NB E5B 1B2

Canada

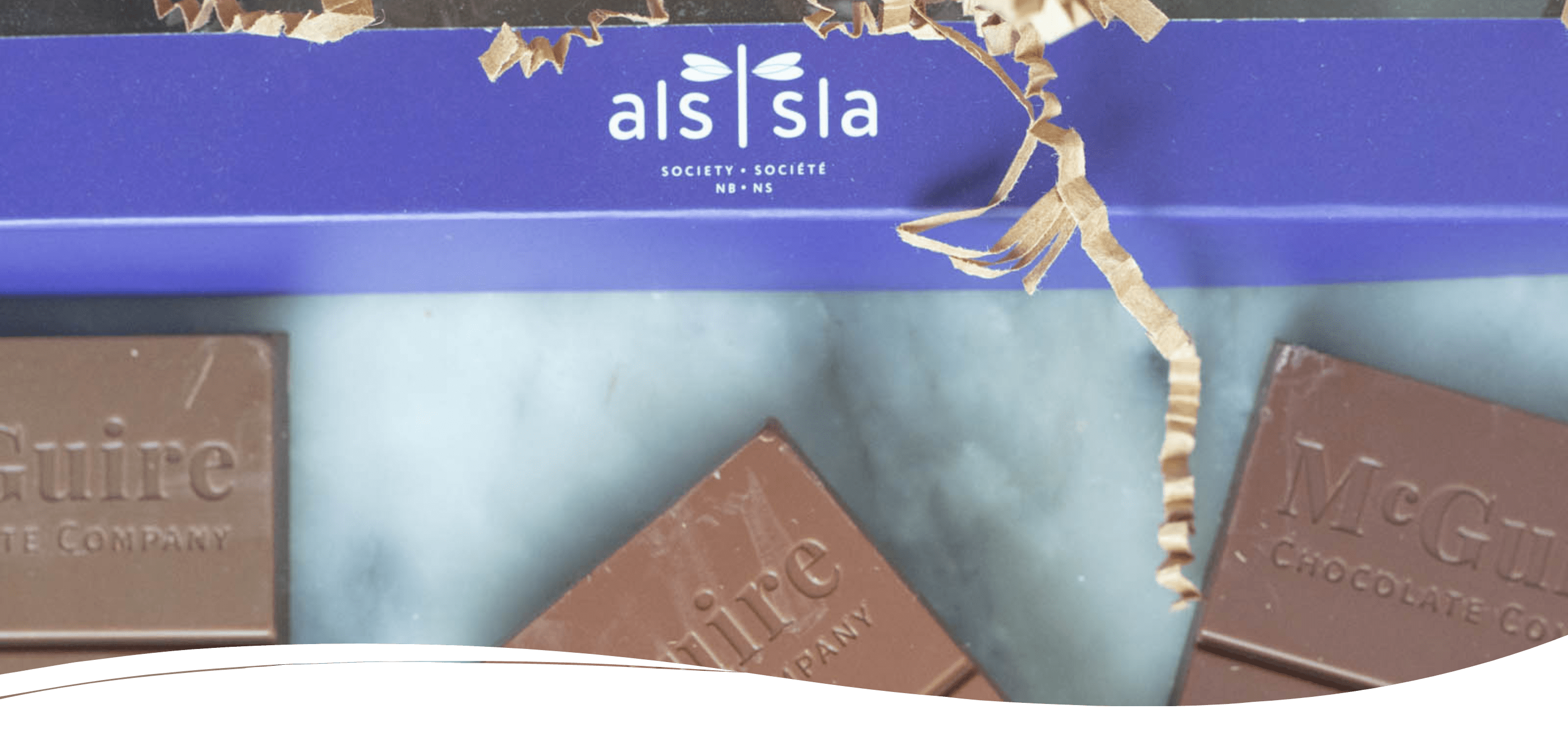

Giving Back

Chocolate with a Cause

McGuire Chocolate has proudly partnered with the ALS Society of New Brunswick and Nova Scotia.

100% of profits from the ALS chocolate boxes will be donated to the ALS Society of NB and NS.

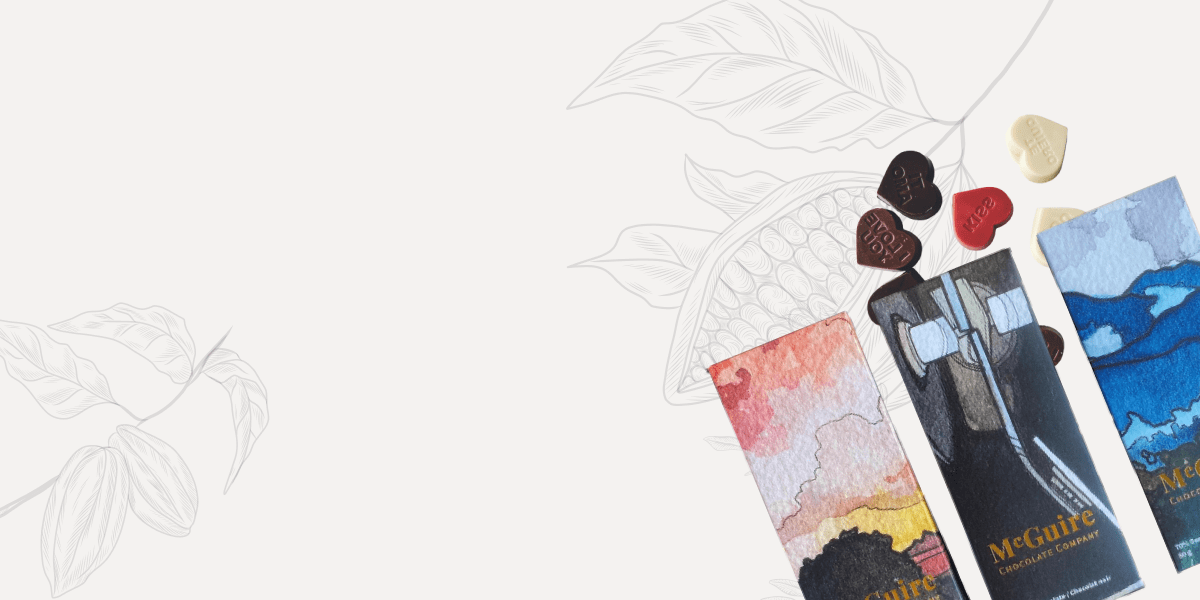

Mission

Our Food Philosophy

We believe food should be simple and easy to understand.

Like the McGuire Chocolate team, our ingredient lists are small and mighty. You will never find lecithin, flavourings, or ingredients you can't pronounce in our chocolate. Only real food here.

We highlight the farmer groups that produce our cacao and also the suppliers that connect us to those farms. Transparency is important to us; we believe it is the key to nurturing a happy and healthy supply chain.

Our Values

We never take short-cuts

We work with high-quality ingredients that you can taste. Our commitment to quality means we'll take our time and process with care. You won't find preservatives, emulsifiers or other commercial additives here.

We are an open book

Our food journey is available for all to see which is why we have a huge window into our chocolate factory and will happily talk shop with anyone interested. We have no tricks or secrets.

Meaningful connections

Bean to bar chocolate is so good that it must be shared. The positive impacts on farmers, local makers, and artists make it a feel-good product but it is the taste that will have you talking.

A labour of love

The Chocolate Making Process

1

Working with fermented cacao

Only about 5% of cacao in the world undergoes a controlled fermentation; due to the specialized knowledge and infrastructure required in remote areas.

2

Transparently and ethically sourced

We publish our supply chain because we are proud of its contributors. You can trace all of our origins back to the farmers and fermentaries.

3

Roasted at different levels

Roasting is the primary flavour influencer that a chocolate maker directly controls. We design, and continually tweak, a unique profile for each one of our cacao bean origins.

4

Remove shells

Cacao beans are roasted in their shells which then have to be removed before grinding. We have built many winnowers over the years to help semi-automate this labour-intensive process.

5

Grinding with ingredients

Melangers stones are made of heavy granite and roll over cacao until the fat naturally liquifies and eventually smooths out. This grinding process takes a week to complete and is where all of the ingredients of chocolate come together.

6

Measure microns

We use a grindometer to measure the micron size of our chocolate near the end of the grinding process. We take our chocolate below 30 microns which is as smooth as the human tongue can detect.

7

Obtain max flavour

The amount of air we exposed the chocolate to during the grind will

harmonize the flavour components and mellow the intensity levels. This process is known as conching.

8

Feel good chocolate

It's easy to feel good while eating world-class chocolate made using only top-notch ingredients from traceable sources.

Working with fermented cacao

1

Only about 5% of cacao in the world undergoes a controlled fermentation; due to the specialized knowledge and infrastructure required in remote areas.

Transparently and ethically sourced

2

We publish our supply chain because we are proud of its contributors. You can trace all of our origins back to the farmers and fermentaries.

Roasted at different levels

3

Roasting is the primary flavour influencer that a chocolate maker directly controls. We design, and continually tweak, a unique profile for each one of our cacao bean origins.

Remove shells

4

Cacao beans are roasted in their shells which then have to be removed before grinding. We have built many winnowers over the years to help semi-automate this labour-intensive process.

Grinding with ingredients

5

Melangers stones are made of heavy granite and roll over cacao until the fat naturally liquifies and eventually smooths out. This grinding process takes a week to complete and is where all of the ingredients of chocolate come together.

Measure microns

6

We use a grindometer to measure the micron size of our chocolate near the end of the grinding process. We take our chocolate below 30 microns which is as smooth as the human tongue can detect.

Obtain max flavour

7

The amount of air we exposed the chocolate to during the grind will

harmonize the flavour components and mellow the intensity levels. This process is known as conching.

Feel good chocolate

8

It's easy to feel good while eating world-class chocolate made using only top-notch ingredients from traceable sources.