75% Bourbon Dark Chocolate

75% Bourbon Dark Chocolate

McGuire Chocolate

174 Water Street

St. Andrews NB E5B 1B2

Canada

We paired Kokoa Kamili nibs with Bulleit Bourbon because of their complimentary citrus notes.

The Kokoa Kamili fermentary, located in the Kilimanjaro valley, purchases wet cacao beans from almost 3000 smallholder farmers, most of whom farm between 0.5-2 acres of cocoa. Prior to the founding of Kokoa Kamili the only cacao companies in the country were focused on buying large volumes of commodity cocoa for cheap, cheap, cheap. The result: Tanzania had one of the lowest GDP per capita rates in the world for rural cacao farmers.

In Kokoa Kamili’s first year alone their farmers received the highest prices in Tanzania for their cocoa. Kokoa Kamili pays a premium - well above the market rate - to farmers for their ‘wet’ cocoa, and conducts its own fermentation and drying. By taking over the fermentation and drying process, Kokoa Kamili can produce more consistent, higher quality cocoa beans. This method gives farmers a reduced workload, along with greater compensation, and the farmers are paid immediately after the cooperative receives its wet beans.

On the front of this chocolate bar you will find an image of two whiskey glasses. Cheers!

Kokoa Kamili was among those first 10 that we experimented with and is the only one that we still work with 5 years later.

The artwork on the package was completed by Kristofer Parley. Kristofer is a Victoria based artist who focuses on working with water colours and ink. We met him our first year in St. Andrews while he was staying in town for the KIRA Artist Residency. For more information on him please visit the Staying Creative Studio.

Cacao beans produced by Kokoa Kamili in Tanzania and sourced from: Meridian Cacao.

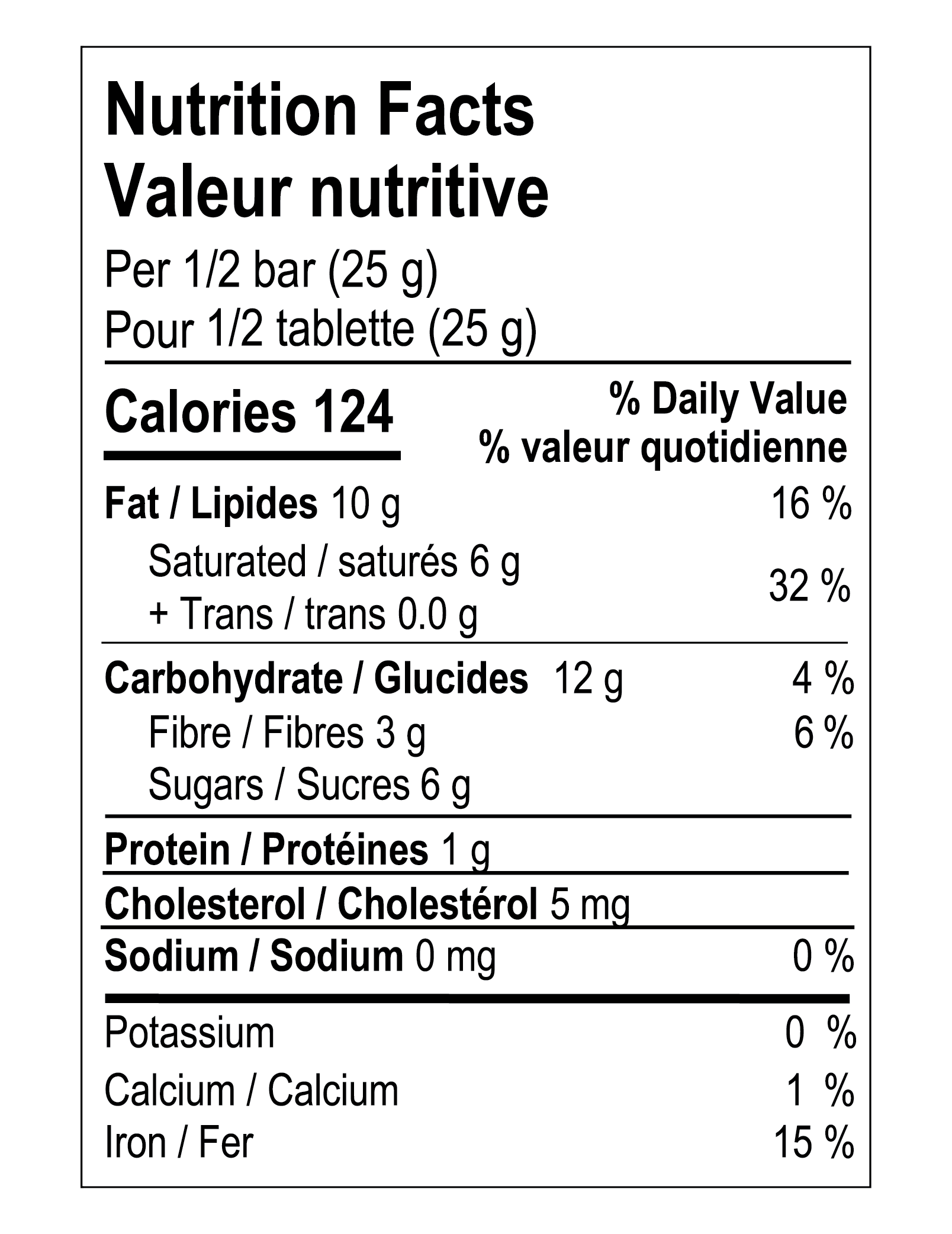

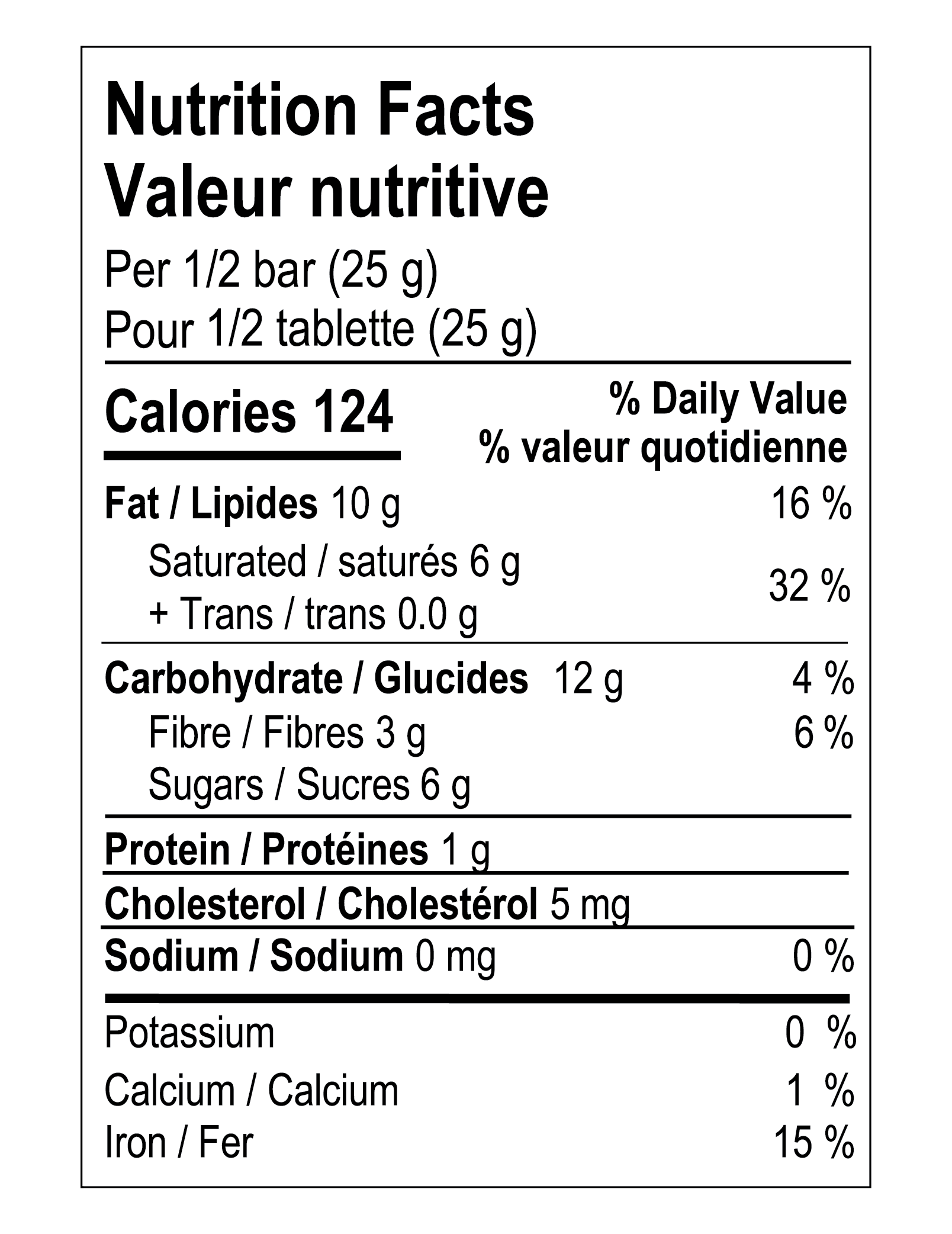

Ingredients: Cacao beans*, Cane sugar*, Cocoa butter*, Bourbon.

May contain: Peanuts, Tree nuts.

Ingrédients: Fèves de cacao*, Sucre de canne*, Beurre de cacao, Bourbon.

Peut contenir: Des arachides, Noix.

*Certified organic / Certifié biologique

Changing the Focus

Industry Evolution

The 20th century chocolate industry was built on a few extremely large companies - making all of the chocolate in the world and distributing it through chocolatiers. Single origin wasn’t even niche – it just wasn’t a thing. In this model we lost all transparency to the source and cacao was treated as a commodity. There are even futures contracts for cacao traded on global exchanges. This treatment is similar to other commodities like oil and gold. The problem is that when we accept cacao as a commodity, we imply that all cacao is created equal. In turn, the effect on farmers is that they emphasize yield over quality. Why go through the investment and effort of having your cacao properly fermented if it’s not going to fetch a premium in the marketplace?

When we list our cacao source – not simply the country but the farmer group – you know that your chocolate bar is made from cacao the supports farmer premiums for a product that goes the extra mile.

High Quality

Fermented Cacao

An astonishing amount of effort goes into well fermented cacao. The fermentation process must occur within 2 days of being cut from the tree and cacao trees grow in some of the most remote areas of the world. It is not a commercial crop as it requires strong biodiversity to thrive.

On top of this, the fermentation process is capital intensive as it requires infrastructure and technical expertise. A tall order for cacao farmers who (for the most part) live below the poverty line and get squeezed by commodity cacao prices.

Tracability

Is the chocolate you eat transparently traded?

The best indicator is if the farm is listed on the chocolate bar. When the cacao source is listed – not simply the country but the farmer group – you know that your chocolate bar is made from cacao the supports farmer premiums for a product that goes the extra mile.

farmers first

ETHICAL AND TRACEABLE

Fair trade certifications do not go nearly far enough to ensure farmers are actually treated fairly in the chocolate industry. When your cacao sources are traceable you can be confident there is accountability in the supply chain.

A labour of love

The Chocolate Making Process

1

Working with fermented cacao

Only about 5% of cacao in the world undergoes a controlled fermentation due to the specialized knowledge and infrastructure required in remote areas.

2

Transparently and ethically sourced

We publish our supply chain because we are proud of its contributors. You can trace all of our origins back to the farmers and fermentaries.

3

Roasted at different levels

Roasting is the primary flavour influencer that a chocolate maker directly controls. We design, and continuely tweak, a unique profile for each one of our cacao bean origins.

4

Shell removal

Cacao beans are roasted in their shells which then have to be removed before grinding. We have built many winnowers over the years to help semi-automate this labour intensive process.

5

Grinding the ingredients

Melangers stones are made of heavy granite and roll over cacao until the fat naturally liquifies and eventually smooths out. This grinding process takes a week to complete and is where all of the ingredients of chocolate come together.

6

Measure microns

We use a grindometer to measure the micron size of our chocolate near the end of the grinding process. We take our chocolate below 30 microns which is as smooth as the human tongue can detect.

7

Obtain max flavor

The amount of air we exposed the chocolate to during the grind will harmonize the flavour components and mellow the insentity levels.

8

Feel good chocolate

It's easy to feel good while eating world-class chocolate made using only top notch ingredients from traceable sources.

Working with fermented cacao

1

Only about 5% of cacao in the world undergoes a controlled fermentation due to the specialized knowledge and infrastructure required in remote areas.

Transparently and ethically sourced

2

We publish our supply chain because we are proud of its contributors. You can trace all of our origins back to the farmers and fermentaries.

Roasted at different levels

3

Roasting is the primary flavour influencer that a chocolate maker directly controls. We design, and continuely tweak, a unique profile for each one of our cacao bean origins.

Shell removal

4

Cacao beans are roasted in their shells which then have to be removed before grinding. We have built many winnowers over the years to help semi-automate this labour intensive process.

Grinding the ingredients

5

Melangers stones are made of heavy granite and roll over cacao until the fat naturally liquifies and eventually smooths out. This grinding process takes a week to complete and is where all of the ingredients of chocolate come together.

Measure microns

6

We use a grindometer to measure the micron size of our chocolate near the end of the grinding process. We take our chocolate below 30 microns which is as smooth as the human tongue can detect.

Obtain max flavor

7

The amount of air we exposed the chocolate to during the grind will harmonize the flavour components and mellow the insentity levels.

Feel good chocolate

8

It's easy to feel good while eating world-class chocolate made using only top notch ingredients from traceable sources.